You can order the parts from here, in a variety of materials.

Here are pictures of the part files, with their names.

Step 1

You will need two of these. Check the fit of the Yoke T and Yoke Extend, and trim if necessary to achieve a tight fit and a straight part. Separate the parts, put glue on both, and fit them back together. Wipe off any excess glue, and allow to dry thoroughly, possibly overnight, depending on the glue. I used "household cement". Despite the tight fit of the parts, gluing really is necessary. There's quite a bit of bending load on it. Not gluing will allow too much flex, and it really needs to be stiff.

Step 2

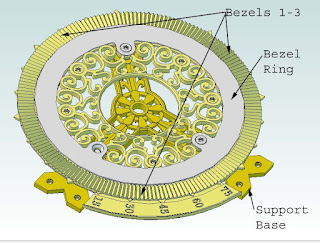

Look on the back of bezels 1 and 2, and find the index marks. Piece them together, as shown in the figure, then turn the grouping right-side-up.

Step 3

Slip the bezel ring screws (csink head) through the bezel ring, and loosely thread into the support base. Make sure the notch in the support base is oriented as shown in the figure.

Step 4

Piece together and slip Dome Capture Segments between the Support Base and Bezel Ring, as shown. The Support Base should fit into notches in the Dome Capture. Do not tighten the screws yet.

Step 5

Carefully turn the assembly over, and slip the Bezel sections under the Bezel Ring. The Bezel Ring will lock into the groove in the Bezel segments. Tighten all three screws until snug.

Step 6

These are the voyages of...

Fit the Mount Extensions onto the Support Base. Lock them together using the Support Bushings, as shown. Both Hi bushings go on one Extension, and Lo's on the other. Either way is fine. Make sure to use the correct length screw, and slip an angle roller under each screw. Slip a Scale Clip into place on each before tightening the screws. Leave the screws out or very loose on one side for now.

Step 7

Push Knob Bushing all the way into the knob until seated. A very small amount of the bushing should show through the bottom.

Pus the Arm Pin all the way into the Arm. Push the Arm Bushing onto the part of the Arm Pin that extends through the bottom. The Arm Bushing should contact the bottom of the Arm.

Step 8

Insert the Yoke Pin into the Arm until flush. Insert the Arm Pin into the hole in the center of the support base. Push the Gear Blank onto the Arm Pin, then secure into place with the Key.

Step 9

Assemble Yokes, et all onto the Yoke Pin, as shown in the picture. The Angle Rollers create a v-track for the inside of the Scotch Yokes. Tighten the Acorn Nut.

Step 10

Slide the Zero Scales onto the Yoke arms, and secure each with a Zero screw. Lay the lower Yoke into the Low Bushings, and secure with Angle Rollers and Low Bushing Screws. The Rollers and Bushings create a v-track for the Yoke to slide in. Secure the higher Yoke in the same manner, on the High Bushings.

Step 11

Align the Dome notches with the assembly, slip it into the Dome Capture Ring, and rotate it clockwise until it stops. I found it helpful to line up the screw holes first, then look at the notch that lets it fit over the support base/mount extension frame. Then clock it to the other edge of that notch, carefully push the dome edge into the slot, and clock it back until the holes line up again. I found it to be tricky, and might try wetting the edge lightly with water next time, to slightly lub it. Insert the Dome Screw to secure the dome in place.

All Done! Now wasn't that easy? No? Well, then doesn't it look cool?

Howdy LAL!

ReplyDeleteI really like this design, thanks so much for sharing it! I'm kind of a fan of sin&cos, have posters of unit circles on my walls.

Can you make a video clip of this in action? Just so that I can show it to people when explaining things.

Hopefully I can print one of these out and use it in real life! :D

There is nothing on this page describing what this device is, why it was created, and what it does.

ReplyDeleteHere is what I tell people about how to present content on their web pages...

It is often difficult to determine why content providers have a web site.

The first thing a Web site should say is:

Why there is a Web Site, Product, or Service,

then How you do what you do,

then What you do.

Why is always first, What (the product) is last. It is a mistake to begin with What, only mentioning Why somewhere obscure in the Site. People only want to know why you do what you do, not what you are selling. At the top of the Home page should be simple text stating Why you exist over some friendly pictures and white space, not long lists of what you are selling.

-----

You need more examples in your web site; Pictures, charts of configurations, minimum requirements, comments from users of their experiences.